Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

In today's dynamic market, businesses are constantly seeking innovative ways to enhance their products and differentiate themselves from competitors. One such method is manual encapsulation, a technique that plays a crucial role in various industries. If you're unfamiliar with this process, don't worry—by the end of this article, you'll have a clear understanding of manual encapsulation and why OEM (Original Equipment Manufacturer) solutions are essential.

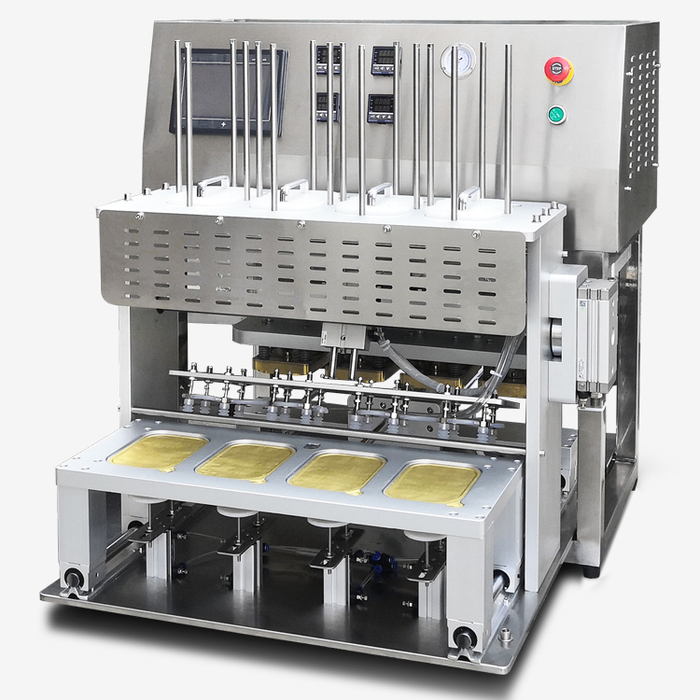

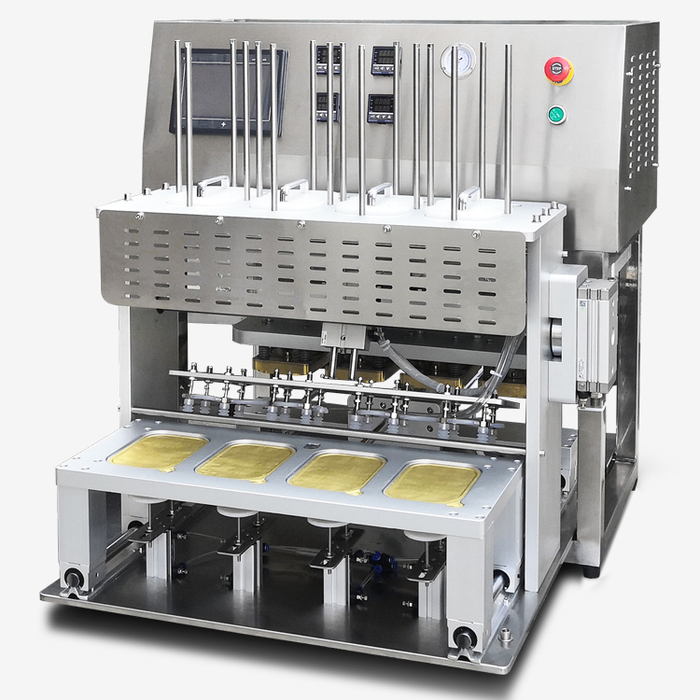

Manual encapsulation refers to the process of enclosing a product or substance within a protective layer or shell manually. This technique is commonly used to preserve the integrity of sensitive materials, protect them from environmental factors, or provide a customized appearance. The encapsulation process can be applied to a wide range of products, from electronic components and pharmaceuticals to cosmetics and food items.

The manual aspect of encapsulation involves hands-on work, where skilled technicians carefully handle and process each item. This is often preferred for small-batch or highly specialized products where precision and attention to detail are paramount.

1. Customization and Flexibility: One of the primary advantages of manual encapsulation is its flexibility. Manufacturers can easily adapt the process to suit specific product requirements, whether it's a unique shape, size, or material. This level of customization is particularly valuable for niche markets or specialized products.

2. Quality Control: Manual encapsulation allows for rigorous quality control at every stage of the process. Skilled technicians can inspect each item individually, ensuring that it meets the highest standards of quality and performance. This hands-on approach minimizes the risk of defects and ensures that the final product is of superior quality.

3. Enhanced Protection: Encapsulation serves as a protective barrier, shielding sensitive materials from environmental factors such as moisture, heat, and light. This is especially important for products like pharmaceuticals and electronic components that require a controlled environment to maintain their efficacy and longevity.

4. Aesthetic Appeal: Manual encapsulation also offers opportunities for enhancing the visual appeal of a product. By using various encapsulation techniques, manufacturers can create aesthetically pleasing designs and finishes that attract consumers and elevate the overall product experience.

OEM solutions play a significant role in the manual encapsulation process. An OEM is a company that manufactures products or components that are then branded and sold by another company. When it comes to manual encapsulation, partnering with an OEM offers several advantages:

1. Expertise and Experience: OEMs specializing in manual encapsulation bring a wealth of expertise and experience to the table. They have the knowledge and skills required to handle complex encapsulation tasks and ensure that the process is carried out efficiently and effectively.

2. Cost-Effectiveness: Working with an OEM can be a cost-effective solution for businesses looking to implement manual encapsulation. OEMs often have established processes and equipment that allow them to perform encapsulation tasks at a lower cost compared to setting up an in-house operation.

3. Scalability: OEMs can easily scale their operations to meet the needs of different clients. Whether you're looking for a small batch of customized products or a large volume of encapsulated items, an OEM can adjust their processes accordingly to accommodate your requirements.

4. Focus on Core Competencies: By outsourcing manual encapsulation to an OEM, businesses can focus on their core competencies and strategic initiatives. This allows companies to allocate resources more effectively and concentrate on areas such as product development, marketing, and customer service.

Manual encapsulation finds applications in a wide range of industries, each with its unique requirements and challenges. Here are a few examples:

1. Pharmaceuticals: In the pharmaceutical industry, manual encapsulation is used to enclose drugs and supplements in protective capsules. This ensures the stability and efficacy of the medication while providing a convenient method of administration for patients.

2. Electronics: For electronic components, manual encapsulation protects sensitive circuitry from environmental factors such as moisture and dust. This is crucial for maintaining the performance and reliability of electronic devices.

3. Cosmetics: In the cosmetics industry, manual encapsulation can be used to create innovative product formulations and packaging. Encapsulated ingredients can provide controlled release and enhanced effectiveness in skincare and beauty products.

4. Food Industry: Manual encapsulation is also employed in the food industry to preserve flavors, vitamins, and other sensitive ingredients. This helps extend the shelf life of food products and maintain their nutritional value.

As technology continues to evolve, the field of manual encapsulation is also undergoing transformation. Some emerging trends include:

1. Advanced Materials: The development of new encapsulation materials and technologies is expanding the possibilities for manual encapsulation. Innovations in materials science are leading to more effective and sustainable encapsulation solutions.

2. Automation Integration: While manual encapsulation remains a hands-on process, there is a growing trend toward integrating automation technologies. This hybrid approach combines the precision of manual work with the efficiency of automated systems.

3. Customization and Personalization: As consumer preferences shift toward personalized products, manual encapsulation will play a key role in providing tailored solutions. Manufacturers will continue to explore ways to offer customized encapsulation options to meet the diverse needs of their customers.

Manual encapsulation is a versatile and valuable technique used across various industries to protect and enhance products. The expertise and flexibility offered by manual encapsulation, combined with the advantages of partnering with an OEM, make it a compelling choice for businesses seeking high-quality and customized solutions. As technology advances and consumer demands evolve, the future of manual encapsulation holds exciting possibilities, promising even more innovative and effective solutions for businesses and consumers alike.

By understanding the intricacies of manual encapsulation and leveraging OEM expertise, businesses can stay ahead of the curve and deliver exceptional products that meet the highest standards of quality and performance.