Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

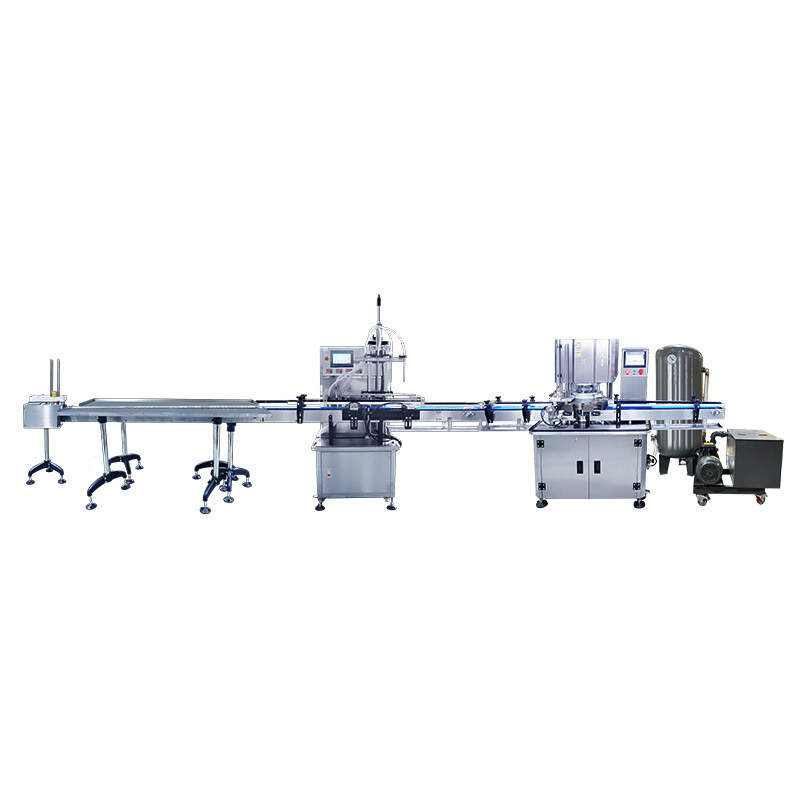

In today’s fast-paced manufacturing landscape, businesses are constantly seeking innovative solutions to enhance efficiency and productivity. Imagine a world where machines seamlessly integrate into production lines, minimizing human error and maximizing output. This vision is becoming a reality with fully automatic encapsulation machinery. As industries evolve, understanding the importance of these advanced systems can be the key to staying competitive.

Fully automatic encapsulation machinery is designed to encapsulate various products, from pharmaceuticals to food items, in a protective layer. This process not only enhances the product’s shelf life but also ensures safety and quality. The technology leverages automation to streamline operations, reducing manual labor and increasing precision.

Increased Efficiency

Enhanced Product Quality

Cost Savings

Flexibility and Customization

Pharmaceutical Industry

The pharmaceutical sector is one of the primary users of encapsulation machinery. Capsules can deliver medications in a precise dosage, improving patient compliance and effectiveness.

Food Industry

In the food industry, encapsulation can protect flavors and nutrients, ensuring that products maintain their quality during storage and transportation.

Cosmetics and Personal Care

From vitamins to essential oils, encapsulation technology allows the cosmetic industry to enhance product stability and efficacy.

When selecting a fully automatic sealing machinery manufacturer, consider the following factors:

Reputation and Experience

Technology and Innovation

Customization Options

After-Sales Support

The field of encapsulation is continuously evolving. Key trends include:

Sustainable Practices: Manufacturers are increasingly focusing on eco-friendly materials and processes. Sustainable encapsulation solutions are becoming a priority for many companies.

Integration with Smart Technology: The rise of Industry 4.0 is influencing encapsulation machinery. Smart machines equipped with IoT capabilities can provide real-time data and analytics, enhancing operational efficiency.

R&D in New Materials: Research into innovative encapsulation materials, such as biodegradable options, is gaining momentum. This development aligns with global sustainability goals.

As the demand for high-quality products continues to rise, the importance of fully automatic encapsulation machinery cannot be overstated. By investing in advanced encapsulation technology, companies can ensure they meet market needs while optimizing their operations. Embracing these innovations not only enhances productivity but also paves the way for a more sustainable future in manufacturing.

We are a professional manufacturer of fully automatic encapsulation machinery. Our machines are designed to enhance production processes. They streamline operations, increase efficiency, and elevate product quality. Investing in our technology can take your production to new heights. Achieve unparalleled levels of operational excellence with our advanced machinery. Contact us to learn more about how we can benefit your business. Let us partner with you on your journey to success.