Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

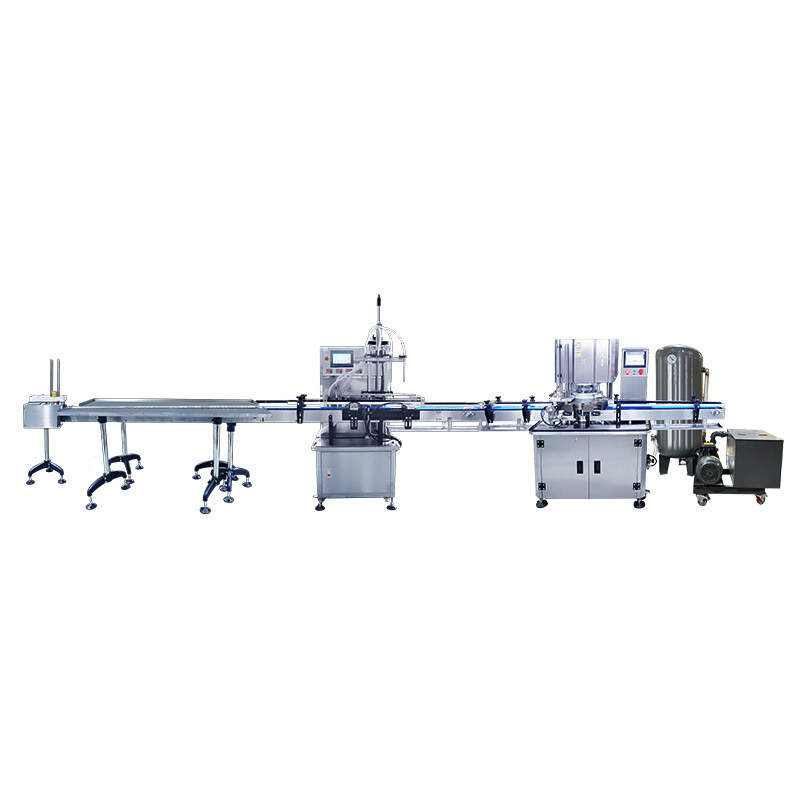

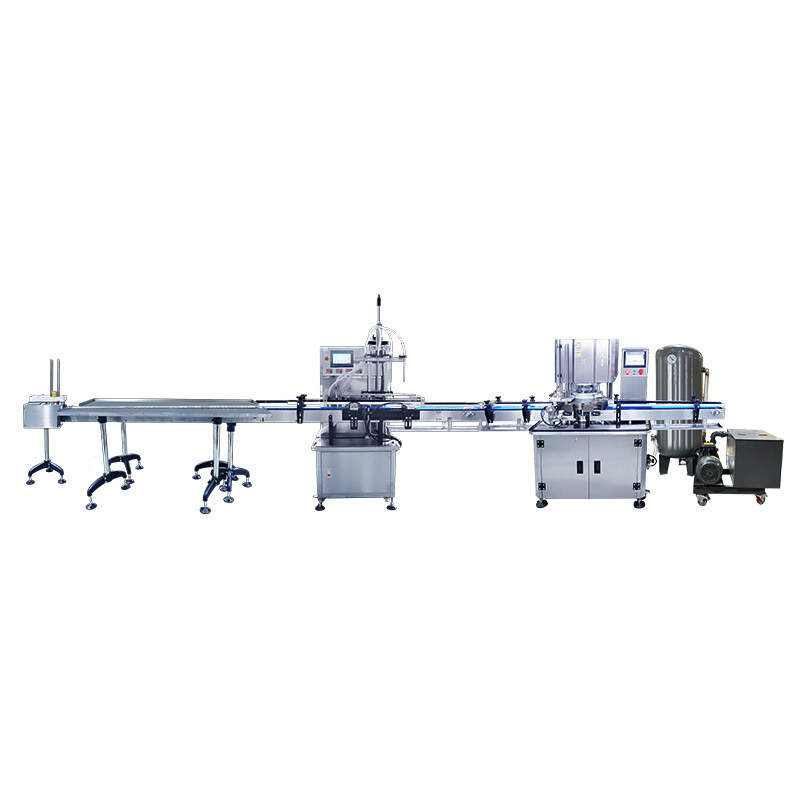

Welcome to another exciting installment in our manufacturing innovation series! Today, we're diving deep into the fascinating world of Fully Automatic Encapsulation Machinery OEM (Original Equipment Manufacturer). If you're passionate about the cutting-edge technologies transforming the industrial landscape, buckle up because we're about to embark on a thrilling ride.

What is Fully Automatic Encapsulation Machinery OEM?

First things first, let's decode the term "Fully Automatic Encapsulation Machinery OEM." Simply put, it refers to the collaboration between a manufacturer specializing in producing automated encapsulation machines and a company that integrates these machines into their production line, branding them as their own. OEM partnerships are nothing new; they've been around since the 1970s, when large multinational corporations started outsourcing production to reduce costs and focus on core competencies. However, the fully automatic encapsulation machinery niche takes this concept to a whole new level.

Encapsulation, in the context of manufacturing, involves enclosing or protecting delicate materials within a protective shell or coating. This process is vital in industries like pharmaceuticals, electronics, food processing, and even the automotive sector. Fully automatic encapsulation machinery automates this intricate process, ensuring precision, efficiency, and scalability.

Why Does It Matter?

The significance of fully automatic encapsulation machinery OEM lies in its ability to revolutionize production processes. Here are a few reasons why this technology matters:

Efficiency Boost: Automation eliminates manual labor, reducing the risk of human error and speeding up production times significantly. Imagine a pharmaceutical company that can encapsulate thousands of pills per minute without compromising on quality – that's the power of fully automatic encapsulation machinery.

Cost Reduction: By outsourcing production to specialized OEMs, companies can save on infrastructure, training, and maintenance costs. The OEM handles the manufacturing aspect, allowing the client company to focus on product development, marketing, and sales.

Scalability: As demand grows, fully automatic machines can be easily scaled up to meet production targets. This flexibility ensures that companies can quickly adapt to market changes without significant disruptions.

Quality Control: Automation ensures consistency in product quality. Machines operate within tight tolerances, ensuring every encapsulated product meets the highest standards.

How Does It Work?

Fully automatic encapsulation machinery is a complex system designed to perform multiple tasks seamlessly. Here's a simplified breakdown of the encapsulation process:

Feeding System: Raw materials are automatically fed into the machine via a precise feeding system. This system ensures a continuous and even flow of materials, minimizing waste and downtime.

Encapsulation Chamber: Inside the chamber, the materials undergo the encapsulation process. This could involve coating, molding, or any other technique specific to the industry. The chamber is designed to be fully enclosed and controlled, ensuring a sterile environment for sensitive materials.

Inspection & Sorting: After encapsulation, each product undergoes rigorous inspection to ensure it meets quality standards. Defective products are automatically sorted out, and only the best make it to the next stage.

Packaging & Labeling: Finally, the encapsulated products are packaged and labeled, ready for distribution. The packaging process is also automated, ensuring consistency and efficiency.

Innovations in Fully Automatic Encapsulation Machinery

The world of fully automatic encapsulation machinery is constantly evolving, with new innovations emerging every day. Here are a few trends that are shaping the industry:

Integration with IoT: The Internet of Things (IoT) is transforming the way machines communicate and operate. Fully automatic encapsulation machinery is no exception. With IoT integration, machines can share data in real-time, enabling predictive maintenance, remote monitoring, and optimized production schedules.

Advanced Sensors & Controls: The latest machines are equipped with high-precision sensors and advanced control systems. These sensors monitor every aspect of the encapsulation process, from material flow to product quality, ensuring precision and consistency.

Artificial Intelligence & Machine Learning: AI and ML algorithms are being integrated into encapsulation machinery, enabling self-optimization and continuous improvement. Machines can learn from past data, identify patterns, and make adjustments to optimize performance.

Sustainability: As environmental concerns grow, manufacturers are looking for ways to reduce their carbon footprint. Fully automatic encapsulation machinery is designed to minimize waste, conserve energy, and use eco-friendly materials.

Case Study: Engenuity's OEM Partnership in the Oil & Gas Industry

Background:

Engenuity, a prominent provider of control automation and data integration solutions, has been instrumental in transforming the oil and gas industry through its innovative technology and strategic partnerships. By focusing on advanced technologies tailored specifically for the sector, Engenuity has enabled oil and gas companies to improve efficiency, safety, and cost-effectiveness in their operations.

Partnership Overview:

One of Engenuity's most successful partnerships has been with an original equipment manufacturer (OEM) in the oil and gas industry. This partnership was forged to address a pressing need in the sector: the validation and maintenance of drilling facilities' safety and integrity through hydrostatic pressure testing. These tests, typically performed manually on blowout preventers (BOPs) and well control equipment, were time-consuming, costly, and prone to errors.

Challenges:

The oil and gas industry faces numerous challenges related to ensuring the safety and reliability of its drilling facilities. One major challenge is the frequent need for hydrostatic pressure testing of critical equipment, which must be completed regularly to maintain operational standards. These manual tests were not only expensive but also unreliable, as human error could compromise the accuracy of the results.

Solution:

Engenuity collaborated with its OEM partner to develop a fully automated testing and reporting solution. The solution leveraged Engenuity's expertise in control automation and data integration, along with Opto 22's groov EPIC (edge programmable industrial controller). This integrated system enabled seamless process control, real-time notifications (via text and email), and detailed process history storage and replication.

Implementation:

The automated testing system was implemented across the OEM's client base, which included major oil and gas companies. By automating the testing process, Engenuity and its partner were able to significantly reduce the time and cost associated with manual testing. The system's reliability and accuracy also ensured that drilling facilities were operating safely and efficiently, minimizing the risk of accidents and downtime.

Benefits:

The partnership between Engenuity and the OEM has delivered numerous benefits to the oil and gas industry:

Cost savings: Automated testing eliminated the need for manual labor, reducing the overall cost of maintenance and validation.

Increased safety: By reducing human error and providing real-time monitoring, the automated system ensured that drilling facilities were operating safely at all times.

Improved efficiency: Automated testing streamlined the process, allowing oil and gas companies to focus on other critical tasks.

Data-driven decision-making: The detailed process history storage and replication enabled companies to analyze performance data and make informed decisions about future operations.

Looking ahead, several trends and developments will further propel the growth and innovation within this sector:

As companies seek to differentiate their products in the market, the demand for customized encapsulation machinery will rise. OEMs will need to offer flexible designs and configurations that can be tailored to specific production requirements and product specifications. This will require advanced engineering capabilities and a deep understanding of various industries' unique needs.

Fully automatic encapsulation machinery will become more flexible and modular, allowing for easy integration into existing production lines and quick adaptation to changing production demands. Modular designs will facilitate the replacement or upgrading of individual components, reducing downtime and improving overall efficiency.

The integration of IoT, AI, and machine learning technologies will continue to drive the digital transformation of encapsulation machinery. Machines will become more interconnected, enabling real-time monitoring, predictive maintenance, and optimized production cycles. This will lead to improved decision-making, reduced downtime, and increased productivity.

As automation becomes more prevalent in manufacturing, ensuring the safety of operators and complying with industry regulations will be paramount. OEMs will continue to invest in safety features and technologies, such as automated shut-off systems, emergency stop buttons, and user-friendly interfaces. Additionally, machines will be designed to comply with relevant international standards and regulations, ensuring seamless integration into global supply chains.

Sustainability will remain a critical consideration in the design and operation of fully automatic encapsulation machinery. Manufacturers will focus on reducing energy consumption, minimizing waste, and using eco-friendly materials. This will not only help reduce the environmental impact of production but also align with consumers' growing preference for sustainable products.

Conclusion:

In conclusion, the journey through the world of Fully Automatic Encapsulation Machinery OEM is a testament to the relentless pursuit of innovation and efficiency in the manufacturing industry. By partnering with specialized OEMs, companies can harness the power of automation to streamline production processes, reduce costs, and enhance product quality.

The integration of cutting-edge technologies such as IoT, advanced sensors, AI, and ML is pushing the boundaries of what's possible, enabling manufacturers to achieve levels of precision and scalability that were unimaginable just a few years ago.

Moreover, the focus on sustainability in the design and operation of these machines aligns with the global shift towards eco-friendly practices. By minimizing waste, conserving energy, and using eco-friendly materials, manufacturers can contribute to a greener future while maintaining a competitive edge.

As the manufacturing landscape continues to evolve, it's clear that Fully Automatic Encapsulation Machinery OEM will play a pivotal role in shaping the future of industries worldwide. With its ability to transform production processes, reduce costs, and enhance product quality, this technology is poised to revolutionize the way we make things.

So, if you're an entrepreneur, innovator, or simply someone passionate about the future of manufacturing, keep your eyes peeled for the latest developments in Fully Automatic Encapsulation Machinery OEM. The future is bright, and the possibilities are endless.